Can MEWP incidents be prevented through design?

December 12, 2024

The U.S. is 10-15 years behind the rest of the world when it comes to safe practices when working at height, according to safety consultant and industry veteran TJ Lyons.

“This is an embarrassment to the U.S.,” Lyons said.

TJ Lyons speaks at the Working at Height Conference on Nov. 20. (Photo: Eason Photography)

TJ Lyons speaks at the Working at Height Conference on Nov. 20. (Photo: Eason Photography)

Known as the developer of the “Ladders Last” campaign, Lyons spoke about prevention through design recently at ALH and IPAF’s inaugural Working at Height Conference.

Lyons addressed how moving from risk management to risk elimination is key for construction firms, manufacturers and contractors.

One example he noted was a jobsite fatality in 2011 involving a straight-boom telehandler. Due to the boom’s lowered/stowed position, views from one side of the cab were obstructed, causing the operator of the machine not to see a fellow worker who was ran over by the machine, leading to his death.

“It was designed as a killing machine,” Lyons said. “One of the biggest barriers in the U.S. are the manufacturers making the tools and equipment.”

Lyons went on to explain that within the U.S., oftentimes changes and additions are made to standards’ language following fatalities and/or accidents. He says a better – and safer – approach is to prevent these instances from occurring in the first place through design and engineering.

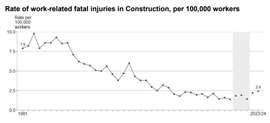

(Graphic: Labour Force Survey/Health and Safety Executive)

(Graphic: Labour Force Survey/Health and Safety Executive)

Lyons added that the oft-heard excuse, “But we have always done it this way,” is also a major contributor to accidents and fatalities on jobs – and that many, if not all, could be prevented if manufacturers designed risks out of equipment and tools in the first place.

Lyons showed the UK construction industry’s sharp decline in fatal injury rates after the implementation of its Construction, Design and Management (CDM) regulations in 2015.

“We need to make solutions for workers,” Lyons concluded. “Eliminate the hazard and you eliminate the injury.”

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

CONNECT WITH THE TEAM