44th Annual Engine Yearbook: Fueling a New Future

02 August 2023

It’s generally acknowledged that the world is in the beginning stages of a massive energy transition from fossil fuels to alternative low- and zero-emissions power sources. And interestingly enough, so are engines, as can be seen in the pages of the 44th annual Engine Yearbook that follow.

Though there are those who believe combustion engine technology is shortly destined for the ash heap of history, the reality is that new fuel system technology and new fuels may keep engines on the job longer – perhaps much longer – than previously imagined.

Several factors are at play, notably economics and time. Literally all things electric, particularly medium- and heavy-duty trucks, off-highway equipment, cost two to three times more than their engine powered equivalents. A refuse truck that normally sells for $300,000 is $600,000 when electrified. Similarly, the diesel-powered version of one global manufacturer’s compact track loader sells for around $85,000 – the all-electric CTL is more than $300,000.

Though at this time there is no real sense about what hydrogen fuel cell technology will cost (and the fact that fuel cell systems also require batteries), it’s fair to conclude that they won’t be much less expensive than purely electric designs. Yes, there are operating and maintenance advantages to electric powertrains, but acquisition costs remain a significant hurdle to adoption, which Jack Roberts discussed in his Street Smarts column elsewhere in this issue.

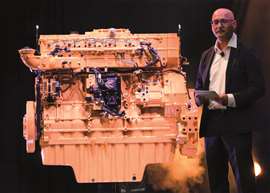

At the debut of its new C13D diesel engine, Caterpillar Vice President Jaz Gill said the company was “dedicated to diesel.” (Photo: Caterpillar)

At the debut of its new C13D diesel engine, Caterpillar Vice President Jaz Gill said the company was “dedicated to diesel.” (Photo: Caterpillar)

At the same time, it must be noted that new engine and aftertreatment technologies required by regulations such as the EPA’s Clean Trucks or the California Air Resources Board’s Clean Fleets program will certainly make engine systems much more expensive over time. But it’s unlikely to be anything approaching the orders of magnitude of electric and fuel cell systems.

Another revealing clue as to the short and medium-term prospects for engines can be deduced by adhering to the classic old saying “follow the money.” A number of engine manufacturers – AGCO, Caterpillar, Cummins, Deere, Kubota, Yanmar – have recently launched new engine platforms. Caterpillar was particularly emphatic when launching its new C13D diesel at ConExpo, with one company official proclaiming that Cat is “committed to diesel.”

Similarly, it’s difficult to find an engine company these days that isn’t hard at work in development with hydrogen engines, with some, notably JCB, Cummins and Liebherr, set to bring engines to market as soon as next year. If combustion engines were such a dead end and unlikely to survive beyond the decade, it hardly seems credible that those companies would be spending that kind of money on new product development.

In the same vein, a number of manufacturers are laying out big bucks to improve and modernize their facilities for building engines. One example is Cummins, which is investing more than a billion dollars to upgrade its engine manufacturing sites in Indiana, North Carolina and New York. Through its Accelera by Cummins operation, Cummins has probably been as bullish – and heavily invested – as any company out there when it comes to fostering new and alternative power technologies. Yet it’s also spending a whole lot of cash on developing and manufacturing new engines.

What all this suggests is that the companies that have made their livelihoods for decades by understanding what products their customers need to power vehicles and machines, then delivering them at competitive prices, aren’t quite ready to bury combustion engines just yet.

JCB is one of several engine manufacturers preparing to go to market with hydrogen engines as soon as next year. (Photo: JCB)

JCB is one of several engine manufacturers preparing to go to market with hydrogen engines as soon as next year. (Photo: JCB)

And why would they when fuel suppliers, including the oil companies that have specialized in refining and delivering liquid fuels for the last 140 years, are beginning to roll out new generations of low-and zero-carbon fuels, such as hydrotreated vegetable oil (HVO), renewable bio-diesel and other nature-based fuel products? As Dr. Ingo Wintruff, managing director of Liebherr’s combustion engine business noted at last year’s Diesel Progress Summit, “The concern is not the combustion engine but the fuel that is burned.”

It’s not a stretch to suggest that those advocating most passionately for the environment might want to support what’s happening with engines and fuels, as it represents the only way to make progress on decarbonization and improve air quality right now, with no need to wait for the installation of electric or hydrogen infrastructures. That will be a massive building program akin to constructing a new interstate highway system and while many billions have been dedicated toward that effort, it will take a lot of time to get it done – more likely a matter of decades than years. To quote Gen. Patton, “a good plan, executed violently now, is better than a perfect plan executed next week.” That logic would seem to apply in this instance.

Bringing that concept closer to home, Cummins Chairman Tom Linebarger noted in an interview with Diesel Progress last year that, “carbon emissions are a little bit like compound interest – the more you put out today, the more decarbonization you have to do in the future, because it sits up there and accumulates and causes challenges today. If we can make impacts today, we’ll have less of a problem in the future.” Engines can and will have that impact, as soon as the next two years.

A final indication of the staying power of combustion engines can be gleaned from the accompanying chart detailing NAFTA engine production, provided by Power Systems Research, the Minnesota-based supplier of global production data and forecasts for the engine and power equipment market. While there are some power bands that have ticked down marginally, the comeback from the COVID year of 2020 has continued in most segments and that doesn’t seem likely to change in the short term.

We remember being advised not too long ago that the Engine Yearbook probably wasn’t going to be around much longer, fading away with the subject matter. However we expect to be chronicling the activities and achievements of internal combustion engines for some time to come. And we hope you’ll come along for the ride.

Click here to access the complete edition of the 44th Annual Engine Yearbook.

AGCO POWER

Linnavuori, Finland

+358 20 786 3600

www.agcopower.com

POWER RANGE

Diesel: 79 to 476 hp (59 to 355 kW)

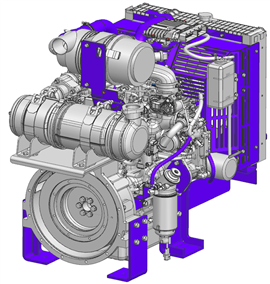

The AGCO CORE75 engine. (All following photos courtesy of manufacturer)

The AGCO CORE75 engine. (All following photos courtesy of manufacturer)

Engine News

Major launches for AGCO Power over the past year covered the October 2022 introduction of the CORE engine platform and the new 7.5 L turbo CORE75, together with an update for the 84LXTN 8.4 L diesel engine.

The CORE75 is available as both low- and high-speed variants, delivering respectively maximum power of 299250 hp (223 kW) at between 1500 and 1700 rpm and 1450 Nm of torque, and 335 hp (250 kW) at 1850 rpm (same torque output).

The engine is compliant with Tier 4 final/Stage 5 regulations without using an EGR system, while both variants are HVO (hydrotreated vegetable oil) compatible. AGCO states the engines have best-in-class fuel economy of 188 g/KWh.

On the back of a $100 million investment, production of the new CORE75 started in late 2022. Part of that development budget was directed at an all-new machining line, which is scheduled to come online in 2023.

The 84LXTN is an updated version of the existing 84HD engine. Major changes include replacement of the two-stage turbo with a single-stage e-wastegate turbo which is said to reduce complexity and improve reliability. Improvements to the aftertreatment system have supported deletion of the EGR system, which also reduces cooling requirements. Maximum power is 420 hp (313 kW) at 1850 rpm and torque is rated at 1750 Nm at 1500 rpm.

Other recent milestones for AGCO Power include the production of the 100,000th engine at the plant in Changzhou, China (December 2022), and the 30th anniversary of the plant at Mogi das Cruzes in Brazil (March 2023).

AMERICAN HONDA MOTOR CO. INC.

The Honda eGX electric motor.

The Honda eGX electric motor.

Honda Engines (Honda Power Sports & Products)

Alpharetta, Ga.

(678) 339-2600

[email protected] (Troy McCall, engine sales_

engines.honda.com

POWER RANGE

Gasoline: 1 to 24.8 hp

Electric: 2.4 hp

Engine News

Introduced in 2021, the eGX electric motor is the company’s latest product. It is a high-power, three-phase brushless DC power unit. Running at 1800 to 3600 rpm, the motor has internal and external cooling fans to dissipate heat. The integrated motor, power drive unit (PDU) and lithium-ion battery pack incorporate rubber mounts that absorb vibration.

The motor can be operated at temperatures ranging from -15 to 40◦ C (5 to 104◦ F) and stored at -5 to 30◦ C (23 to 86◦ F).

ARROW ENGINE CO.

Tulsa, Okla.

800-331-3662

www.arrowengine.com

POWER RANGE

Diesel: 15 to 156 hp

Gaseous Fuel: 5 to 130 hp

Engine News

Arrow Engine launched a new pair of gaseous-fueled engines based on Kirloskar industrial diesel engines. The KP3 and KP6 engines are certified to stationary, nonroad mobile and emergency standby regulations and target a range of stationary power, power generations and even mobile applications, the company said.

Arrow Engine’s new KP3 natural gas engine.

Arrow Engine’s new KP3 natural gas engine.

The KP3 is an inline, naturally aspirated three-cylinder engine with a bore and stroke of 105 x 120 mm and a displacement of 3.12 L. It utilizes a cast iron block with a single-piece cylinder head and two Stellite valves with hardened seats per cylinder. It is available in ratings from 38 to 44 hp (28 to 33 kW) for 60 Hz applications and 34 to 40 hp (26 to 30 kW) for 50 Hz units.

The KP6 is an inline, six-cylinder naturally aspirated engine with bore and stroke dimensions of 105 x 125 mm and a displacement of 6.5 L. Currently available at a 95 hp (70 kW) rating, it also incorporates a cast iron block, single-piece cylinder head and two Stellite valves and inserts per cylinder.

Both engines can operate on natural gas, wellhead gas and liquid propane. They each use Woodward PG+ engine controls, offer a CAN J1939 communications interface and are telematics compatible. Both engines are also capable of switching between two fuels, the company said.

A turbocharged and charge-air cooled version of the KP3 offering gen-set ratings to 59 kWe will be available later this year, Arrow Engine said.

BRIGGS & STRATTON

Vanguard Commercial Power

Wauwatosa, Wis.

www.vanguardpower.com

POWER RANGE

Gasoline: 4.9 to 40 hp

Gaseous Fuel: 6.5 to 37 hp

CATERPILLAR INC.

Irving, Texas

(830) 386-2600

www.cat.com/industrial

POWER RANGE

Diesel: 10 to 7644 hp

Gasoline: 95 to 5351 hp

Engine News

Caterpillar announced the Cat C13D, a new 13-liter diesel engine platform, designed to achieve best-in-class power density, torque and fuel efficiency for optimizing the performance of heavy-duty off-highway applications.

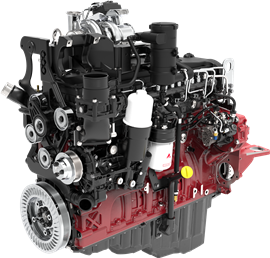

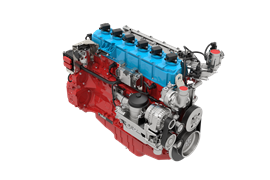

The Cat C13D diesel engine.

The Cat C13D diesel engine.

The inline, six-cylinder C13D engine platform will offer eight power ratings from 456 to 690 hp with up to 3200 Nm of peak torque. Engine mounted aftertreatment and cooling packs will also be available from the factory to reduce installation and validation costs. The C13D will meet the emissions standards of higher regulated markets, such as EU Stage 5, U.S. EPA Tier 4 final, China Non-road IV, Korea Stage V, and Japan 2014, with models available for lesser regulated markets.

By supplying comparable power and torque available from Caterpillar’s current 13 L, 15 L and single-turbo 18 L engine platforms, the company said the C13D platform provides an opportunity for OEMs to downsize the engine and simplify design, assembly and supply chain requirements across multiple applications.

The company said the engine platform offers up to a 20% increase in power and up to 25% more low-speed torque over the previous generation of Cat engines in its power class.

It is designed to perform at altitudes of up to 12,000 ft, reportedly twice as high as legacy Cat engines, and in extreme ambient temperatures as high as 140 F and as low as -40 F with aids.

The C13D engine platform enables the use of renewable liquid fuels such as 100% HVO, B100 distilled biodiesel, and even up to B100 standard biodiesel by working with the local Cat dealer, said the company. Further, its core architecture is designed for the future development of natural gas and hydrogen fuel capabilities.

CUMMINS INC.

Columbus, Ind.

www.cummins.com

POWER RANGE

Diesel: 49 to 4400 hp

Gaseous Fuel: 49 to 2680 hp

On-Highway Engine News

Cummins recently unveiled its new X10 on-highway engine for North America. Expected to launch in 2026, the new inline six-cylinder will replace both the L9 and the X12 with the versatility to serve both medium and heavy-duty applications. It will be compliant with U.S. EPA’s 2027 regulations a full year in advance of the regulations, Cummins said.

Medium-duty ratings range from 320 to 380 hp with torque ratings of 1000 to 1250 lb. ft. at 2100 rpm. For heavy-duty applications, ratings are 350 to 450 hp, with torques ranging from 1350 to 1650 lb.ft. at 1800 rpm.

The diesel version will be available first, with other versions for gaseous fuels – including hydrogen – to be introduced later. The 10 L product slots into Cummins’ product portfolio between the B6.7 and X15 and will serve vocational, transit, pickup and delivery and regional haul customers.

The X10 diesel will first be available in Europe and North America and introduced later in other regions. It will also eventually be available for off-highway applications. Cummins said it will have 75% less NOx emissions than required at launch in 2026 and will be compliant to U.S. EPA’s 2027 regulations as well as upcoming Euro 7 rules, while providing a step change in fuel economy improvement.

The X10 architecture uses a belt-driven, high output 48 V alternator and an optimized aftertreatment heater system. For further reductions in carbon emissions, the engine can be operated on B20 biodiesel or renewable diesel.

Off-Highway Engine News

Cummins unveiled its new fuel-agnostic 15 L engine at ConExpo-Con/Agg. Engineered to operate on diesel, HVO, natural gas/biogas and hydrogen, Cummins said it offers OEMs the opportunity to accelerate the decarbonization of heavy-duty off-highway applications.

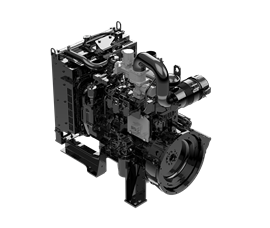

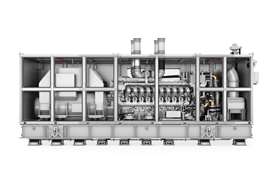

Cummins’ 15 L fuel-agnostic engine platform.

Cummins’ 15 L fuel-agnostic engine platform.

This new platform, designed for the next level of emissions, has a significant increase in power density with a more compact installation envelope enabling OEMs to increase machine capability and productivity with no impact on running cost.

The fuel-agnostic architecture of the 15 L engine utilizes a common base engine with cylinder heads and fuel systems specifically tailored to the specific fuel.

The 15 L hydrogen engine will be available with ratings from 400 to 530 hp with a peak torque of 1917 lb. ft. (2600 Nm). For applications powered by renewable biogas, this engine will offer ratings from 400 to 510 hp with a peak torque of 1843 ft. lb. (2500 Nm) available. The advanced diesel version features will offer a broad power range of 450 to 670 hp, with 2212 lb.ft. (3000 Nm) peak torque.

A key design feature of the new platform is a double overhead camshaft (DOHC) that Cummins said provides significant advances in combustion and thermal efficiency. Friction losses across the engine design have also been reduced and a sculpted block contributes to weight saving. The DOHC design also enables a more efficient integral engine brake to be accommodated, the company said.

DAEDONG CORP.

Daedong’s new power pack with a 1.8 L engine.

Daedong’s new power pack with a 1.8 L engine.

Daegu, South Korea

https://daedong-kioti.com/

POWER RANGE

Diesel: 19 to 55 hp

Engine News

Daedong Corp., parent company of compact equipment brand Kioti, has introduced several new power packs. The 1.2 L engine version weighs 160 kg and has an engine rating of 25 hp (18.3 kW) at 3000 rpm. The 1.8 L version weighs 330 kg and has a rated power of 55 hp (41 kW) at 2600 rpm. The company said it is also working on a power pack with a 140 hp (104.5 kW) 3.8 L engine.

The products meet emissions standards for EPA Tier 4 final, Stage 5 and Korea Stage 5. The company said its power packs are compact and are designed to offer customers durable performance, quality and versatility. They are also designed to make installation and maintenance simple.

DETROIT DIESEL CORP.

Redford, Mich.

https://demanddetroit.com/

POWER RANGE

Diesel: 200 to 600 hp

Corporate News

Late last year, Detroit, the brand of Detroit Detroit Diesel Corp. and the engine and powertrain subsidiary of Daimler Trucks North America, announced a milestone in its heavy-duty engine program with the production of its millionth engine at the Redford, Mich., manufacturing facility.

Covering more than 3 million sq. ft., the Redford plant has been building engines since 1938 and is where the company manufactures its Heavy Duty Engine Platform (HDEP) product family that includes the DD13, DD15 and DD16 engines.

Introduced in 2007, the HDEP engines were jointly developed in Germany, Japan and the United States. HDEP engines are also built in Mannheim, Germany.

Detroit has launched the Detroit Connect Video Capture (DCVC) service, available as a subscription-based option in the Detroit Connect Portal. The proprietary digital service provides an additional layer of safety for users by recording safety events, such as active braking, roll stability events and other various events, allowing for increased visibility into fleet operations.

The newest service available as a supplement to the Detroit Assurance safety system, DCVC provides actual video footage of events when they occur on the road or at a jobsite.

https://www.deutzusa.com/products/diesel-engines

DEUTZ CORP.

Norcross, Ga.

(770) 564-7100

www.deutzamericas.com

POWER RANGE

Diesel: 25 to 835 hp

Gasoline: 52 to 73 hp

Gaseous Fuel: 35 to 73 hp

Hydrogen: 201 to 295 hp

Engine News

Deutz introduced several new engines, including the G2.9L (52 to 73 hp), TCD5.2L (134-228 hp) and TCD18.0L rated 761 to 835 hp. The company said its new engines do not use EGR on the U.S. EPA Tier 4 final and EU Stage 5 emissions variants. Also, smaller emissions aftertreatment (EAT) systems have been implemented. The company said its EAT packaging over the engine’s valve cover will be a factory option on engines under 4.0 L.

The Deutz TCG7.8L H2 hydrogen-fueled engine.

The Deutz TCG7.8L H2 hydrogen-fueled engine.

The introduction of the G2.9L extended the company’s gasoline and propane engine lineup to 73 hp, and that all its new diesel engines can run biodiesel/synthetic diesel fuels.

It has prototypes of the TCG7.8L H2 engine in the field in power generation applications which are running on 100% hydrogen. The company said its goal is to move this engine forward in the next two years. It also plans to start on new hydrogen projects with smaller engines through 2024.

Corporate News

Deutz Corp. picked a location for its newest Deutz Power Center, one that will cover Michigan, Ohio, and parts of northeast Kentucky. Ryan Merry has joined as branch manager for the center in Howell, Mich. He brings 22 years of experience in the equipment rental industry to the role.

With a fully stocked parts counter, Deutz Power Center Great Lakes East will provide regularly scheduled and emergency service of Deutz engines, at the center’s location or by sending a mobile service technician to the customer’s site.

The new location will also provide dedicated application engineering and technical sales resources to OEMs. Customers can purchase new Deutz engines, as well as Deutz Xchange remanufactured engines.

ENGINE DISTRIBUTORS INC. (EDI)

Blackwood, N.J.

(800) 220-2700

www.edi-dist.com

POWER RANGE

Gasoline: 25 to 250 hp

Gaseous Fuel: 25 to 250 hp

Engine News

EDI has been working on a new 5.0 L engine that it said is due to be available by the first quarter of 2024. The company said the engine will produce 165 hp at 2700 rpm and will be designed to run on gasoline, LPG and natural gas.

The company’s hydrogen engines are currently being designed, with production anticipated by late 2024.

FAIRBANKS MORSE DEFENSE (FMD)

Beloit, Wis.

www.FairbanksMorseDefense.com

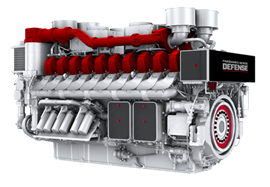

FMD’s nForcer FM 175D engine.

FMD’s nForcer FM 175D engine.

POWER RANGE

Diesel: 4827 to 25,747

Gaseous Fuel: 2100 to 4865 hp

Engine News

Fairbanks Morse Defense has expanded its naval defense capabilities with the nForcer FM 175D engine, reportedly its first engine designed for high-speed applications such as unmanned vessels. The engine will be available with 12, 16 or 20 cylinders and has a 175 mm bore for mechanical or electric propulsion for onboard power generation. Designed for a variety of marine fuel, the engine operates at 1800 to 2000 rpm and has a power output rating of 2333 to 5900 hp (1740 to 4400 kW).

FMD said it anticipates the engine will be ready to integrate with naval fleets within the next two years. Offered by FMD and serviced worldwide, the company said the engine’s proven marine technology (as a MAN Energy Solutions SE licensee) is engineered to ensure reliable operation, extended asset lifecycles and minimal downtime.

FPT INDUSTRIAL NORTH AMERICA

Burr Ridge, Ill.

www.fptindustrial.com

POWER RANGE

Diesel: 49 to 825 hp

Gaseous Fuel: 74 to 245 hp

The F28 Hybrid from FPT Industrial.

The F28 Hybrid from FPT Industrial.

Engine News

FPT Industrial showed its full range of Tier 4 final and Stage 5 2.8 to 16 L engines at ConExpo-Con/Agg in March.

On show was the new F28 engine family. The engines were created with a multi-fuel design and share base components for the diesel, natural gas and hybrid versions. The engines are fully compatible with renewable fuels.

For the North American market, the company offers dedicated solutions with its Tier 4 final no-DPF technology (HI-eSCR system), while global applications are addressed with integrated HI-eSCR2 systems compliant to the EU Stage 5 regulation and dual-certified for Tier 4 final.

It also showed the F28 PowerPack with a compact and pre-validated package to simplify installation. It uses a 2.8 L F28 Tier 4 final/Stage 5 engine rated 75 hp, with 375 Nm (276 lb-ft) of torque and has oil change intervals of 600 hours.

The company showed the F28 Hybrid at ConExpo, as well. It is an engine paired with an e-flywheel, suitable for compact construction equipment and rental units. The 2.8 L F28 Hybrid engine displayed during the Las Vegas event is rated 75 hp, with a 48 V electric motor that adds 27 hp of continuous electric power and up to 40 hp peak power.

Late last year, it showed the FPT XC13, a multi-fuel single-base engine. From diesel to natural gas to hydrogen and renewable fuels, the company said the base engine was designed with multiple versions to offer component standardization and easy integration.

Corporate News

FPT Industrial made minority investment in Blue Energy Commercial Vehicles Private Ltd, a zero-emission truck technology company headquartered in Pune, India, engaged in the manufacturing of clean energy trucks under the brand Blue Energy Motors.

It also announced a strategic partnership that allows Klassen Diesel, a distributor of diesel engines for marine and industrial applications, to represent FPT Indusrtrial in the British Columbia and Yukon provinces of Canada.

A concept vehicle from Prinoth, the Leitwolf h2Motion snow groomer, is equipped with a new FPT XC13 hydrogen engine, a 13 L six-cylinder unit rated 460 hp (338 kW) and with 2000 Nm of torque. The hydrogen fuel is stored in five tanks mounted on the back of the machine for a running time of more than 3 hours. The OEM field-tested the machine on ski slopes during 2022-’23 ski season.

In late 2022, New Holland Agriculture unveiled the T7 Methane Power LNG (liquified natural gas) pre-production prototype tractor that is powered by FPT Industrial’s N67 NG engine. Because LNG allows for greater storage density compared to compressed natural gas, the company said the fuel increases run time without the need for additional tanks.

GUASCOR ENERGY S.A.U.

Zumaia, Spain

+34 943 86 52 00

www.guascor-energy.com/products

POWER RANGE

Diesel: 250 to 1800 hp (marine)

Gaseous Fuel: 338 to 2270 hp

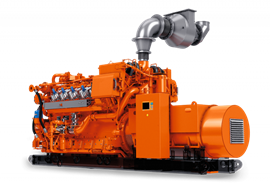

Corporate News

In November, Mutares SE & Co. completed its acquisition of Siemens Energy Engines S.A.U. and related assets. Following the acquisition Guascor Energy recovered its original name and focus as a company with more than 50 years of experience in the design and manufacture of diesel and gaseous-fueled internal combustion engines.

The company offers products and services in distributed power generation, as well as marine diesel engines.

Engine News

Additions to Guascor Energy’s product range include the LCMM G-56HM gas engine. Designed to operate on methane from coal mines, the engine is rated 1600 hp (1240 kW) at 50 Hz. Offering mechanical efficiencies up to 41.7%, the LCMM G-56HM can operate on mine gas with methane contents as low as 9% to 13%, the company said.

Two other gaseous fuel engine ranges, the SL and HM engines, have been tested and proven compatible with propane, Guascor Energy said. Propane engine ratings range from 422 to 1841 hp (315 to 1373 kW) at 50 and 60 Hz. There is also the potential to combine natural gas and propane in any percentage, the company said.

Guascor Energy’s G-S56 gaseous-fueled generator set.

Guascor Energy’s G-S56 gaseous-fueled generator set.

Efficiency improvement in the G-86EM engine based on the experience over 500,000 accumulated running hours. Field and factory performance measurements along our great experience in field have shown a 0.3 % better efficiency, leading to a mechanical efficiency value of 46.9% and an electrical efficiency value of 45.7%, which confirms that this product has the best efficiency in the market for the 2MW power output.

Guascor Energy’s 3L platform is designed to operate on hydrogen-natural gas/biogas blends of 20% to 50%. The company said it is progressing toward 100% hydrogen fueled engines.

Guascor Energy has launched a new on-engine fuel-blending system. This supports the combining of hydrogen with natural gas/biogas or propane at blend ratios as high as 50%. A unique characteristic of the system, the company said, is the ability to seamlessly switch between fuels and fuel blends while maintaining engine performance.

The SL series engines can also now incorporate thermocouples in each cylinder to provide improved engine control and more precise diagnostics and troubleshooting.

Guascor Energy said the maintenance schedules for its H and S series natural gas engines has been increased by 15%, while enabling time to overhaul to as much as 80,000 hours.

The company is also offering its Remote Diagnosis Services with all of its engines. The system combines the company’s expertise combined with modern analytic, detection and diagnostics tools to improve the quality of maintenance and even provide predictive maintenance.

HATZ DIESEL OF NORTH AMERICA

Waukesha, Wis.

www.hatznorthamerica.com

POWER RANGE

Diesel: 2 to 86 hp

Engine News

At ConExpo-Con/Agg, Hatz introduced the latest member of its H50 liquid-cooled engine family targeting mobile and stationary applications. The new 4H50N is an inline four-cylinder naturally aspirated diesel with bore and stroke dimensions of 84 x 88 mm and a displacement of 1.95 L. It is rated 24.7 hp (18.4 kW) at 1800 rpm, with a maximum torque of 89.9 lb. ft. (122 Nm).

The Hatz 4H50 diesel.

The Hatz 4H50 diesel.

Like the other members of the H series, it utilizes a Bosch high-pressure common rail fuel system that delivers injection pressures up to 26,000 psi (1800 bar), a maintenance-free two-valve configuration and a pressurized lubrication system. Engineered to meet EPA Tier 4 and EU Stage 5 emissions regulations, it incorporates a diesel particulate filter (DPF), but requires no exhaust gas recirculation (EGR) or diesel oxidation filter (DOC).

The engine also offers single side servicing of oil, fuel and crankcase breather filters and offers oil change intervals up to 3000 hours, the company said. In addition, all H50 series engines can operate on HVO.

Hatz has added to its flywheel integrated permanent magnet generator (fiPMG) product lineup. The original fiPMG won the New Power Technology award at the 2020 Diesel Progress Summit. The newest PMDC-56-440 combines a 1.4 L 3H50TIC diesel engine rated 53 hp with a compact, Hatz-built synchronous brushless alternator rated 25 kW mounted into the engine flywheel.

At ConExpo, the company launched Hatz Digital Solutions, a series of digital products that enable machines with Hatz engines to be operated and monitored more efficiently. The platform includes Hatz Performance Tracking, which enables remote monitoring of engine operating data, such as speed, fuel consumption, operating hours and location in real time.

Also new is the Hatz Protect+ warranty that enables coverage to be extended up to 60 months or 3000 operating hours for air-cooled engines and up to 5000 hours for the liquid-cooled H-series.

Hatz has also unveiled HDS2lite, a pocket-sized mobile diagnostic tool with no annual license fee. Accessible via a Bluetooth adapter and smartphone app, it is designed to display all essential engine maintenance information in real time.

Corporate News

In late 2022, Hatz rebranded itself from Hatz diesel to simply Hatz, reflecting its expanded power system capabilities.

The company is also establishing Hatz of Latin America, which will be responsible for all sales activities in South America. It will operate out of the Hatz of North America facility in Wisconsin.

HD HYUNDAI INFRACORE

Incheon, South Korea

www.hd-hyundaiengine.com

POWER RANGE

Diesel: 10.8 to 1353 hp

Gaseous Fuel: 174 to 613 hp

Hyundai Doosan Infracore’s new hydrogen engine.

Hyundai Doosan Infracore’s new hydrogen engine.

Engine News

HD Hyundai Infracore (HDI) unveiled its new hydrogen internal combustion engine prototype at ConExpo-Con/Agg. The 11 L engine is rated 402 hp (300 kW) with a maximum torque of 1254 lb. ft. (1700 Nm), and the company said it will meet EPA Tier 4, EU Stage 5 and Euro 7 emissions regulations. With measured CO2 emissions below 1 g/kWh, it can be classified as zero emissions in the EU, HDI said.

HDI said it will leverage its existing engine technology and facilities to reduce costs and accelerate commercialization of the engine, which are targeted toward commercial vehicles such as trucks and large buses, as well as construction equipment, The company said the engines will be validated in 2024 and full-scale mass production is planned for 2025.

Corporate News

In late 2022, HD Hyundai Infracore hit a production milestone with the production and shipment of its 500,000th small G2 diesel engine. The G2 engine family consists of 1.8 to 3.4 L inline three- and four-cylinder engines with ratings ranging from 61 to 135 hp (45 to 99 kW).

The company marked the milestone at its Incheon, Korea, G2 manufacturing facility. Production of the G2 began in late 2012 and the company is aiming to increase annual G2 production capacity from 70,000 to 100,000 engines by creating and expanding external production sites.

INNIO WAUKESHA GAS ENGINE

Waukesha, Wis.

(262) 547-3311

www.innio.com/en/waukesha

POWER RANGE

Gaseous Fuel: 160 to 5000 hp

Engine News

INNIO’s Waukesha said its mobileFLEX engine portfolio, comprised of engines and generator sets, now offers advanced ESM2 controls and an enhanced piston to reduce the emissions and operating costs of oilfield equipment and drill rigs significantly.

Waukesha mobileFLEX engines now include ESM2 with AFR2 controls for increased engine uptime, improved availability, and reduced maintenance costs.

Waukesha mobileFLEX engines now include ESM2 with AFR2 controls for increased engine uptime, improved availability, and reduced maintenance costs.

A natural gas alternative to diesel units, the EPA mobile-certified Waukesha mobileFLEX engines and gen-sets operate on a range of field gases without derate, the company said. Waukesha mobileFLEX products can operate in a variety of altitude and temperature applications and provide transient performance with diesel-like load capacity, handling up to 65% load steps and 100% load shed.

The Engine System Manager (ESM2) with AFR2 controls is designed to allow users to see all engine parameters and trend data, as well as view manuals and service bulletins. Additionally, data analytics enhance controls and performance improvements while giving users total control – all without the need for a laptop computer.

The optimized piston reduces emissions of regulated pollutants such as carbon monoxide, volatile organic compounds, and formaldehyde. While the new technology reduces operating costs, support technicians will not need to retrain because of its similarity to existing components.

A two-rig, 8000-hour field validation to study oil consumption and component wear was carried out across six engines, confirming the lab performance of the pistons and cylinder heads, the company said. Waukesha engines running on 100% field gas from producing wells are also providing power for drilling rigs in West Virginia while offsetting 2000 gal. of diesel fuel per day. The switch to mobileFLEX engines is estimated to cut emissions of nitrogen oxides and particulate matter by more than 99%, carbon monoxide by 34%, and carbon dioxide by 7%. Additionally, reducing truck staff has eliminated approximately 200 diesel fuel deliveries, the company said.

INNIO Waukesha and Detechtion Technologies formed a technology collaboration to monitor and optimize gas engines and compressors. The technology partnership will combine INNIO’s Waukesha engine analytics with Detechtion’s compression monitoring and optimization technology into a single solution for both new and existing gas compressor skids. The cloud-based system will help anticipate unexpected service events, improve energy production and reduce plant downtime while fulfilling ESG standards, INNIO Waukesha said.

Corporate News

INNIO Waukesha has been approved as a member of EPA’s Natural Gas STAR Program, which is intended to facilitate methane emissions reduction technologies and activities among member companies, while communicating successes and lessons learned to employees and other members. The program allows for formation of cross-functional teams with other member companies to implement and voluntarily document methane reduction activities, creating a permanent record of accomplishments in reducing methane emissions.

As part of the group, INNIO Waukesha will have the opportunity to educate and collaborate with Natural Gas STAR Partners on the benefits of using rich-burn engine technology to reduce methane emissions in their day-to-day gas compression operations. The program also facilitates information and technology sharing through workshops and other web-based communications to build a strong network with industry peers to stay current on industry trends, initiatives and the latest technologies.

ISUZU MOTORS AMERICA, LLC

Plymouth, Mich.

(734) 582-9470

www.isuzuengines.com

POWER RANGE

Diesel: 11.8 to 512 hp

Engine News

Isuzu Motors America highlighted its new 4LE2X industrial engine at ConExpo-Con/Agg. The engine targets a range of mobile equipment and generator set applications and is designed to meet EPA Tier 4 and EU Stage 5 exhaust emissions standards, while incorporating value-added features for the North American market.

With bore and stroke dimensions of 85 x 96 mm, the vertical inline four-cylinder diesel engine has an overall displacement of 2.178 L. The turbocharged engine is available with ratings from 40 to 66 hp.

Isuzu has developed a range of pre-validated open power units for generator set applications. The power units are based on the company’s 4J, 4H and 6H diesel engines and are delivered least 90% pre-validated, the company said.

More information on the new power units is available elsewhere in this issue.

Isuzu now offers a new service tool for troubleshooting engine issues. The Isuzu Diagnostic Service Tool (IDST) provides diagnostic trouble codes and automatic engine identification and can read and clear engine ECM codes or read-only aftertreatment dosing control units and perform forced SCR system purges. The tools are available through Isuzu distributors and are effective for diagnosing specific engine-related concerns that may not need major work or expensive downtime, the company said.

Isuzu also offers training programs to customers through some of its distributors in certain parts of the country. The training is intended to address the need for more hands-on training related to general maintenance or troubleshooting turbochargers, SCR systems and fuel injectors.

JCB POWER SYSTEMS

Rocester, England

www.jcb.com/products/engines

POWER RANGE

Diesel: 55 to 212 kW

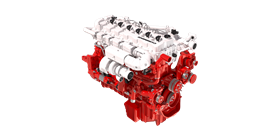

The JCB hydrogen engine on display at ConExpo.

The JCB hydrogen engine on display at ConExpo.

Engine News

JCB held the North American unveiling of its hydrogen internal combustion engine at ConExpo-Con/Agg in March this year. The engine is still under development, but the reveal highlighted the clear direction of travel of R&D at JCB.

The proprietary hydrogen combustion process takes place in a new cylinder head using a port fuel injection system. This helps to ensure the gaseous fuel is combined with air in a concentration required to achieve powerful combustion. A variable geometry turbocharger is used to force air into the cylinder head; a spark ignition is used to ignite the mixture.

In October last year, JCB revealed a new hydrogen refueller. This is designed to deliver compressed hydrogen to work sites in much the same way as diesel is now. The refueller delivers hydrogen fuel to onboard tanks in a process intended to be as similar as possible to diesel refuelling.

As of April this year, JCB is continuing to develop of the hydrogen internal combustion engine. While test versions of the engine have been fitted to both backhoe and telehandler machines (the backhoe has received type approval for use on U.K. highways), the company has not yet announced when the engine or the refueller might go into production.

JOHN DEERE POWER SYSTEMS

Waterloo, Iowa

(800) 533-6446

www.deere.com/en/engines-and-drivetrain/

POWER RANGE

Diesel: 48 to 908 hp

Engine News

John Deere Power Systems (JDPS) has expanded its powertrain offerings to include a new engine architecture, while growing its battery portfolio to include more modular power options.

The new engine architecture is designed to simplify the integration of renewable fuels with internal combustion engines and offers an expanded power range so original equipment manufacturers (OEMs) can install John Deere power into their entire line of equipment, from 48 to 908 hp (36 to 667 kW). The JD4, JD14, and JD18 are the first engines JDPS has engineered with this new architecture.

The JD4 diesel from John Deere Power Systems.

The JD4 diesel from John Deere Power Systems.

Having made its global debut at ConExpo-Con/Agg, the JD4 is the latest addition to Deere’s Next Generation Engine lineup. Rated 161 hp (120 kW), the JD4 is an inline four-cylinder diesel with bore and stroke dimensions of 99 x 128 mm for a displacement of 3.9 L. It incorporates a high-pressure common rail fuel system, wastegate turbocharger and a rear geartrain designed to deliver low noise and high PTO power, said the company. The engine also has an extended single turbocharger range and provides 516 lb.ft. (700 Nm) of maximum torque for improved high-load capacity and productivity.

The JD4 also offers up to three auxiliary drives. This additional power allows flexibility and enables off-boarding for electrification and hybrid applications, the company said. The JD4 will be compatible with EU Stage 3A through Stage 5 emissions levels through common interfaces. The engine is low-NOx ready with planned external cooled exhaust gas recirculation (EGR) and a single overhead cam shaft valve train. The JD4 engine is also compliant with Tier 4 final and Stage 5 emissions levels with no EGR.

John Deere said the path to a sustainable future will not rely solely on one solution and the company is continuing to explore new technologies that incorporate advanced combustion for continued compatibility with renewable fuels.

JDPS has approved current Industrial and G-Drive EU Stage 5 engine lineups (from 2.9 to 18 L) for use with renewable fuels in accordance with EN 15940 standard. This approval also extends to all equipment with Stage 5 engines in the field in the EU.

KAWASAKI ENGINES

Grand Rapids, Mich.

(800) 433-5640

kawasakienginesusa.com

POWER RANGE

Gasoline: 14.5 to 38.5 hp

Engine News

Kawasaki Engines unveiled new engines during Equip Exposition 2022, the lawn and landscape equipment show in Louisville, Ky. The FX EVO engine is an electronic fuel-injected (EFI) powerplant that the company said offers increased power density and improved fuel efficiency. It gets enhanced intake efficiency with a more direct air path and larger flow area for higher performance and improved fuel economy.

The FX EVO gasoline engine from Kawasaki.

The FX EVO gasoline engine from Kawasaki.

EFI integrates an electronic throttle control and an electronic control unit to match mower engine power to cutting load and ground speed. Blades maintain maximum cutting performance through heavy turf, tall grass and up hills, said the company.

EVO engines also include a new cylinder head design with intake and exhaust ports optimized for maximum efficiency and improved flow. The company said its low-pressure casting technology results in high strength, temperature-resistant heads.

The cylinder head has three valves, two intake and one exhaust with increased diameters. Benefits, according to the company, include increased efficiency, improved combustion and reduced exhaust emissions by helping the engine breathe easier.

In direct response to customer demand, the size of the inspection covers and clean-out ports on the new FX EVO were increased for enhanced ease of maintenance. The enlarged structure allows for more efficient grass removal from around the cylinder head and cooling fins and allows access to the intake manifold and fuel injectors without removing the fan housing, said the company.

EVO engines are manufactured at the Kawasaki Engines facility in Maryville, Mo.

KEM EQUIPMENT

Tualatin, Ore.

www.kemequipment.com

POWER RANGE

Gaseous Fuel: 42 to 233 hp

Gasoline: 43 to 104 hp (industrial)

Gasoline: 250 to 600 hp (marine)

KOHLER ENGINES

Reggio Emilia, Italy

www.kohlerengines.com

POWER RANGE

Diesel: 3.3 to 102 kW

Gasoline: 3.3 to 28.3 kW

Gaseous Fuel: 14.5 to 18.6 kW

Engine News

As of August 2022, all Kohler diesel-fueled engines are approved to use hydrotreated vegetable oil (HVO) in the United States, in line with ASTM D975 standard. This confirmation came a few months after European compliance was announced in line with the EN15940 standard.

Kohler KSD engine.

Kohler KSD engine.

The use of HVO, whether pure or blended with conventional diesel, does not require any specific engine modifications or upgrades. However, exhaust gas aftertreatment system remains necessary where already provided.

Alongside HVO, Kohler announced at the Bauma 2022 trade show in Munich, Germany, that hydrogen will be included in the company’s strategy as an alternative fuel, as well. Kohler said it expects the technology to be an uphill road but thinks that hydrogen internal combustion engine will be a cost-effective drop-in solution, and potentially adaptable to most applications.

Benefits include a 100% reduction in CO2 emissions and near-zero emissions but with diesel-like performance.

Also considered within the company’s future-looking strategy will be the all-new KSD engine range: a line-up that promises great flexibility of options and quality performance while maintaining a compact design. The engine, already presented as a multi-fuel platform, will be enhanced by the hybrid model.

In September 2022, the KSD engine won the Engine of the Year Under 175 hp award at the Diesel Progress Summit.

Among the judging criteria for the under-175-hp category for new diesel, natural gas or alternative fuel engines, judges considered innovations relating to engine design, emissions, telemetry/connectivity, control technology, packaging, IoT systems, and ease of maintenance and ownership considerations.

The Diesel Progress Summit’s judging panel said the performance and power density of the KSD were very important factors in their decision, but what especially impressed them were the steps Kohler took to ensure the engines could be easily and effectively serviced and maintained in the field.

Company News

On Sept. 12, 2022, the Kohler Co. Board of Directors elected President and Chief Executive Officer David Kohler to the additional role of Chair of the Board, following the passing of Executive Chairman Herbert V. Kohler, Jr. on Sept. 3 at age 83.

David Kohler chairs the Board of Directors and Executive Committee, in addition to his role as Chief Executive Officer which includes full scope responsibility for the three business groups of Kohler Co. (Kitchen & Bath, Power, Hospitality) and all enterprise functions.

In December 2022, Kohler partnered with Robert Swan, OBE (Order of the British Empire), on his successful expedition across Antarctica to the Geographic South Pole relying solely on renewable energy sources. Like its energy support of Admiral Richard E. Byrd more than 90 years earlier, Kohler equipped Swan’s journey with a customized Kohler generator that utilized a Kohler diesel engine fueled by HVO and a microgrid system controlled by Heila EDGE technology.

In April 2023, Kohler Co. announced the evolution of its Power business to Kohler Energy, aligning with Kohler’s strategy of providing energy resilience to homes, businesses, and communities around the world.

The company celebrates in 2023 its 150th anniversary, having been founded in 1873.

KUBOTA ENGINE AMERICA CORP.

Lincolnshire, Ill.

(847) 955-2500

[email protected]; [email protected]

www.kubotaengine.com

POWER RANGE

Diesel: 6 to 210 hp

Gasoline: 30 to 81 hp

Gaseous Fuel: 25.2 to 83.3 hp

Engine News

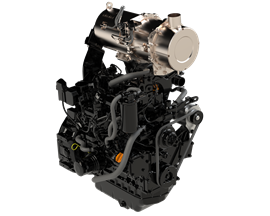

Kubota launched its newest small diesel engine to the North American market at ConExpo-Con/Agg. Originally unveiled in Europe, the D1105-K is a 1.123 L, three-cylinder diesel engine rated output is 24.8 hp (18.5 kW) at 3000 rpm, with peak torque of 53.4 lb. ft. (72.4 Nm) at 2200 rpm.

The next generation of the company’s compact diesel engine range designed to meet the latest exhaust emissions regulations in North America, Europe and China, the D1105-K incorporates Kubota’s proprietary TVCR combustion system technology that combines the company’s original electronically controlled Three-Vortex Combustion System technology with a specially designed compact common rail fuel system. The result is a reduction of engine emissions, including black smoke during cold starts, and an improvement in fuel economy of up to 5% compared to its predecessor. As an additional benefit, no aftertreatment is needed, Kubota said.

Kubota unveiled two new diesel-electric hybrid systems at ConExpo. The D1803 P1 Hybrid combines a three-cylinder, 1.8 L Kubota D1803 diesel engine rated 49.6 hp (37 kW) with an integrated motor-generator embedded within the flywheel housing. The 10 kW motor-generator is used to provide a power assist for brief periods when high output is demanded, Kubota said.

The D1105 P2 Hybrid was one of two new hybrid systems Kubota debuted at ConExpo.

The D1105 P2 Hybrid was one of two new hybrid systems Kubota debuted at ConExpo.

The D1105 P2 Hybrid pairs a 1.123 L, D1105 naturally aspirated diesel engine rated 24.8 hp (18.5 kW) with the same 10 kW motor-generator that delivers power that can be used to augment the engine horsepower in high-load situations or enables the engine to be switched off completely for all-electric motor drive.

The two new hybrids join the Kubota P0 Micro Hybrid system that was unveiled in 2020 and is scheduled to go into production this year.

More information on Kubota’s hybrids will be included in the July-August issue of Diesel Progress.

Kubota announced that HVO is also approved for use in its diesel engines in the United States. The company announced that HVO was approved for its engines in Europe last year. HVO and gas to liquid (GTL) fuels can be swapped for conventional diesel fuel and can be mixed with any approved fuel without compromising engine performance, the company said.

Also at ConExpo, Kubota unveiled its first industrial hydrogen engine. Based on the WG3800 spark-ignited engine, the 3.8 L, inline four-cylinder engine is rated 114 hp (85 kW) and maintains the accessory locations and overall footprint of the existing gaseous-fueled engine.

LIEBHERR COMPONENTS

Bulle, Switzerland

www.liebherr.com/engines

POWER RANGE

Diesel: 130 to 4290 kW 174 to 5752 hp

Engine News

Liebherr reported that it has recently made significant investments in developing its hydrogen engine and related test facilities. Prototype engines have been in testing since 2020. Different injection and combustion technologies, including port fuel injection (PFI) and direct injection (DI) have also been assessed. Prototypes with these features have been running since 2021.

Liebherr’s H964 hydrogen engine.

Liebherr’s H964 hydrogen engine.

The first machine using a 100% hydrogen-fuel internal combustion engine is the Liebherr R 9XX H2 crawler excavator, which won an Innovation Award at Bauma 2022.

Encouraged by the results using PFI technology, Liebherr has been conducting further R&D on DI technology. In mid-2022, the company launched its H964 four-cylinder engine prototype using direct injection, which injects hydrogen into the combustion chamber. Direct injection offers increased combustion efficiency potential and power density, making hydrogen engines a feasible alternative to diesel engines, Liebherr said. The 9.0 L H964 has also returned “encouraging” results in terms of CO2 and NOx emissions.

The Liebherr components segment said it is expecting to start production of hydrogen engines by 2025. In the meantime, the company is researching fuel injection to optimize power density. Several research programs are currently underway, including a dual fuel engine which can use hydrogen ignited by hydrotreated vegetable oil (HVO) – or on full HVO.

LISTER PETTER

Gloucestershire, England

www.listerpetter.com

POWER RANGE

Diesel: 5.5 to 800 kW

Engine News

Lister Petter has been producing engines for more than 150 years. The latest addition to that long heritage came in mid-2022, with the introduction of the company’s first Stage 5-compliant LP311EG1 engine.

Described as ‘a new generation of the special off-road engine’, the three-cylinder 1.1 L unit features a Bosch common rail fuel injection system and ECU to control fuel delivery. All of this is in a compact design which features components and configuration which have been developed over years of innovation.

The engine has a high temperature capability, with operating parameters extending to 50ᵒC. Featuring standard SAE connectivity, the engine combines low cost, fuel efficiency and low maintenance requirements.

MAN ENGINES

Pompano Beach, Fla.

www.man-engines.com

POWER RANGE

Diesel: 110 to 1418 kW

Gaseous Fuel: 50 to 735 kW

Engine News

MAN Engines presented its new V12X engine series at Cannes Yachting Festival 2022. With the newly developed V12 engine for yacht applications, the company said it is now offering its customers an output of 2200 hp (1618 kW) from a 30 L engine.

The MAN V12X-2200 achieves its output of 2200 hp at 2300 rpm from a 138 mm bore and 165 mm stroke.

Compared with the company’s previous most powerful yacht engine – the V12-2000 with 2000 hp (1471 kW) – the displacement of the V12X has been increased by more than 5 L and the maximum torque from 6500 Nm to 7350 Nm.

Off-road engines from MAN Engines are now approved for use with renewable diesel and HVO.

Off-road engines from MAN Engines are now approved for use with renewable diesel and HVO.

The V12X is based on a new basic engine, incorporating much from the current V12 engine series, which continues to cover yacht outputs of up to 2000 hp (1471 kW). Findings from the E3872 stationary gas engine developed in parallel complement the development, said the company.

This counterpart for power and heat generation is based on the same basic engine and was presented for the first time back at the end of 2021.

The company has approved all its marine engines from the current range for use with renewable diesel fuel in line with the standard EN15940 in Europe and the U.S. specification ASTM D975.

The company said this will allow customers to replace conventional petroleum-based diesel fuel with “green” or renewable diesel fuel. Renewable diesel fuel is obtained from waste and residues of animal and plant origin, cellulosic biomass such as crop residues, but also hydrotreated vegetable oils (HVO).

On May 10, 2022, MAN Engines put its first two dual fuel hydrogen-powered engines for work boats into operation. These are two 12-cylinder MAN D2862 LE448 engines, each with an output of 749 kW (1019 hp) at 2100 rpm.

The engines are IMO Tier III-certified and equipped with a selective catalytic reduction exhaust gas aftertreatment system. The V12 engines have been prepared for dual fuel operation by MAN Engines and supplemented with a hydrogen injection system by development partner CMB.Tech.

The engine is used on a hydrogen-powered crew transfer vessel (CTV), the Hydrocat 48 from Windcat Workboats. MAN Engines uses a conventional diesel marine engine in which hydrogen is introduced into the charge air via an adapter and is added to the combustion cycle. The combustion process is thereby started according to the diesel principle, said the company, which requires the injection of approximately 5% diesel fuel. The diesel fuel common rail injection parameters have been optimized for dual fuel operation. CO2 tailpipe emissions are reduced through the use of hydrogen by an average of approximately 50%, and even up to 80% as a peak value, reported the company.

A further advantage of using the conventional diesel engine is easy handling when it comes to maintenance and service. Moreover, pure diesel operation can continue without interruption if the hydrogen supply is exhausted.

MITSUBISHI TURBOCHARGER AND ENGINE AMERICA INC.

Itasca, Ill.

www.mitsubishi-engine.com

www.mtea-us.com

POWER RANGE

Diesel: 6.2 hp to 88.5 hp, 898 hp to 2923 hp (Industrial Engines)

Diesel: 429 hp to 1676 hp (Marine Engines)

Natural Gas: 603 hp to 2011 hp

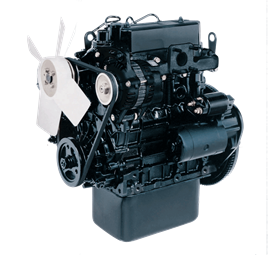

Small Engine News

Mitsubishi continues to offer its small diesel engines, the L and SL lineup of EPA Tier 4 engines that incorporate a mechanical/electronic governor and atmospheric pressure sensor. And the EU Stage 5 L and SL engines continue to be supplied with a mechanical governor.

New to the Mitsubishi small diesel engine family is a L2E constant speed engine. The 0.635 L engine is rated at 4.6 kW at 1500rpm. It meets EU Stage 5 with a mechanical governor.

The Mitsubishi L3E diesel is available as a variable or constant speed engine.

The Mitsubishi L3E diesel is available as a variable or constant speed engine.

On its D03CJ variable speed engine, the 1.655 L rated 36 hp, Mitsubishi added two additional ratings. It has been joined by a 41.5 hp and 48.2 hp engine, each rated at 2500 rpm and equipped with a turbocharger and charge-air cooler. They also incorporate common rail fuel injection technology along with a diesel particulate filter (DPF) and diesel oxidation catalyst (DOC). They do not use exhaust gas recirculation (EGR).

The company’s small diesel engine product line also includes the L2E constant speed engine. Sized at 0.635 L, it is rated at 5.2 kW at 1800rpm. The meets Tier 4 final with a mechanical governor.

Among its L3E variable and constant speed engines, 0.952 Lis rated 15.8 hp at 2400 rpm, while the L3E constant speed is rated at 9 kW at 1800 rpm.

The S3L2 variable and constant speed engine is sized at 1.319 L and rated 23.8 hp at 2500 rpm; while the S3L2 constant speed version is rated 13.7 kW at 1800rpm.

The S4L2 constant speed engine is 1.758L L and rated 18.4 kW at 1800 rpm.

The D03CJ variable speed engine has a size of 1.655 L and a rating of 36 hp at 2500 rpm. It is turbocharged and charge-air cooled and the company said it will also incorporate common rail fuel injection technology along with a diesel particulate filter (DPF) and diesel oxidation catalyst (DOC) but without exhaust gas recirculation (EGR). It has higher horsepower ratings, smaller displacement and the fuel consumption is 16% better than the engines they replaced (SQ Series).

The 3.331 L D04EG variable speed engines are available with two ratings of 48.2 hp and 72.4 hp at 2250 rpm. The 48.2 hp engine is naturally aspirated and the 72.4 hp engine is turbocharged, with a charge-air cooler, common rail fuel injection technology, diesel oxidation catalyst (DOC) and exhaust gas recirculation (EGR).

Lastly, the 3.3 L D04EG constant speed engine is rated at 66 kW at 1800 rpm. This engine meets Tier 3 standards for stationary emergency use and incorporates a mechanical governor.

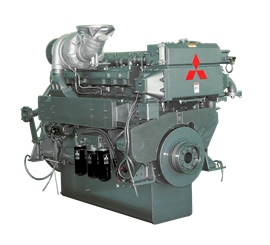

Marine Engine News

The Mitsubishi S6R-T2MPTK2 marine engine designed for South America.

The Mitsubishi S6R-T2MPTK2 marine engine designed for South America.

Mitsubishi also offers diesel engines for marine applications, ranging from 429 hp to 1676 hp for North America and a product line ranging from 429-2526 hp for the South American market.

This year, the North American market has an additional option to consider; the S12R-Y3MPTAW-6, rated 1100 hp at 1800 rpm. The company said it introduced the engine to meet the growing demand for repowering solutions in the marine propulsion industry. It has a greater displacement, more mass (for heavy-duty application) and better durability. The engine model remains all-mechanical.

For the South American region, engine S6R-T2MPTK2 is offered as C-rating, 818 hp at 1637 rpm and as B-rating, 927 hp at 1696 rpm. The company said it expects the solution is expected to be especially well received in the Brazilian region of Manaus. The company said the region in northwest Brazil continues to show potential, as Mitsubishi continues to invest and establish key relationships with the support of its official marine engine distributor Riomor Naval, which will represent the brand in Brazil’s Amazon region.

Natural Gas Engine News

Mitsubishi also offers the 450kWe GS6R2, a 30 L six-cylinder natural gas engine. The company’s natural gas Miller-cycle engine lineup offers outputs from 450 kW to 1500 kW, operating at 1200 rpm for extra longevity and efficiency. The engines are equipped with two-stage intercoolers, improving thermal efficiency by 10% more than single-stage intercooled engines.

Tailored for power generation and combined heat and power (CHP) applications, the GSR natural gas engines combine lean-burn pre-chamber combustion technology, custom-matched Mitsubishi turbochargers, and in-house developed control system. Selected models offer 0.5 g/kWh NOx emission capability without SCR and 85% total efficiency in CHP applications.

NAVISTAR INC.

Lisle, Ill.

www.navistar.com

POWER RANGE

Diesel: 370 to 515 hp

Engine News

During ConExpo-Con/Agg, Navistar a new variation of its International S13 Integrated Powertrain, designed for the company’s vocational truck offering. It introduced the engine, transmission and aftertreatment package to the on-highway market in August 2022, when it was first available in the International LT and RH Series truck models.

The 13 L Navistar S13 diesel engine.

The 13 L Navistar S13 diesel engine.

Developed from a clean sheet design, the S13 Integrated Powertrain consists of three distinct components – an engine, the International T14 transmission (a 14-speed automated manual transmission) and an aftertreatment system – all developed concurrently to ensure maximized compatibility and integration between systems.

The company said the S13 Integrated Powertrain maximizes performance and capitalizes on efficiency made possible through its modular design which enabled efficient cross-brand development and production throughout Traton Group, while still allowing for regional adaptation and validation of the S13 Integrated Powertrain for the North American market.

For Traton, the Navistar system represented the first group-wide demonstration of a modular solution.

The 13 L S13 diesel engine uses a clean-burn combustion strategy and a reduction of friction and pumping losses. It uses selective catalytic reduction (SCR) technology as the primary emissions reduction technology. Navistar said the absence of an exhaust gas recirculation (EGR) cooler allows for nearly 100% of exhaust to flow to the fixed geometry turbocharger. Additionally, the engine operates on low revolutions and high torque which it said equates to fewer fuel injections and less fuel consumption, delivering up to 515 hp and 1850 lb-ft of torque.

To keep temperatures at an optimal range and extend service intervals, the aftertreatment system includes a dual-stage SCR catalyst system in a one-box design.

The S13 Integrated Powertrain will be manufactured at Navistar’s Huntsville Powertrain Manufacturing Plant in Huntsville, Ala.

ORIGIN ENGINES

Kearney, Neb.

(877) 667-6360

www.OriginEngines.com

POWER RANGE

Gasoline: 35 to 174 hp

LPG: 35 to 280 hp

Gaseous Fuel: 35 to 670 hp

Origin’s new 3.6 L spark-ignited engine.

Origin’s new 3.6 L spark-ignited engine.

Engine News

Origin Engines officially released its inline four-cylinder 3.6 L engine into the marketplace. The engine is offered in natural gas, propane and gasoline configurations, and the turbocharged/charge-air cooled configuration offers a 80 kWe rating (107 hp mechanical). The 3.6 L adds to the company’s portfolio of industrial engines, which are available in naturally aspirated or turbocharged configurations for gasoline, LP, natural gas and wellhead gas.

In addition to the 3.6 L engine market release, Origin has also released a 23.9 L, V12 engine, a heavy-duty gasified product offering a maximum rating of 525 kWe/704 hp mechanical. It targets prime, demand response and standby power generation applications.

Origin Engines’ products are manufactured in the U.S. and engineered for heavy industrial use. The company’s products are utilized in a broad range of prime and standby power generation, including oil & gas, agricultural pumping, forestry equipment, industrial power unit and mobile industrial applications.

Origin said its entire product line is EPA emissions certified for prime power and standby applications.

Corporate News

Origin Engines recently completed a 60,000 sq.ft. campus expansion, which includes the addition of a fully automated CNC block machining line capable of machining an engine block from a raw casting to finished block at high precision and tolerances. Able to run unmanned, 24/7, the expansion will nearly double the current engine block output.

PERKINS ENGINES CO. LTD.

Peterborough, England

+44 (0)1733 583000

www.perkins.com

POWER RANGE

Diesel: 5.3 to 2794 hp

Engine News

Perkins has launched new power solution capabilities to help OEMs navigate the global energy transition. Most recently, Perkins demonstrated smarter ways customers can cut development time and costs, by showing its next-generation integrated powertrain program. The end-to-end diesel-electric hybrid powertrain, which it said is highly configurable for a wide range of off-highway applications, consisted of a scalable 48 V battery module, powershift transmission, 20 kW motor-generator unit, inverter and an advanced energy control module.

A diesel-electric hybrid powerplant from Perkins.

A diesel-electric hybrid powerplant from Perkins.

Perkins has continued to invest in new engine technologies, including dual label certification for EU Stage 5 and U.S. EPA Tier 4 final. By optimizing the efficiency of the entire engine system from the air intake to the end of the exhaust pipe, Perkins said it has developed a full range of engines with an integrated suite of advanced technologies that not only reduce GHG emissions, but also deliver significant improvements in power density, performance and operating efficiency. While every industrial Perkins engine from the 400 Series through the 2800 Series can use lower-carbon intensity fuels that meet the leading industry diesel fuel specifications.

Additionally, Perkins recently showcased its connectivity solutions with hardware reading important engine data, displayed to the customer as timely insights. For OEMs with their own in-house telematics solution, an API based service which receives engine data is provided. From this, Perkins delivers useful insights to enhance the service provided by the OEM to their customer, aiding the customer’s productivity.

Corporate News

During the year, Perkins announced its participation in two UK Government “Red Diesel Replacement” projects.

In one project, Perkins was developing an internal combustion engine that runs on renewable dimethyl ether (rDME) and in the second, Perkins and its project partners were demonstrating a number of solutions based upon both ammonia and hydrogen as fuels for decarbonizing heavy-duty engines.

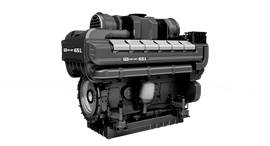

POWER SOLUTIONS INTERNATIONAL (PSI)

Wood Dale, Ill.

www.psiengines.com

PSI has recently expanded its range of engines.

PSI has recently expanded its range of engines.

POWER RANGE

Diesel: 910 to 4291 hp

Gasoline: 34 to 295 hp

Gaseous Fuel: 34 to 1436 hp

Engine News

In partnership with Chinese engine manufacturer Weichai, PSI has recently extended its range of diesel engines with the introduction of 66- and 88 L versions. These join the existing lineup of 20-, 40-, and 55-liter diesel engines.

According to PSI, the 66 L version can deliver up to 2700 KWm (1 KWm is equivalent to 1000 W of mechanical power). The 88 L version is rated up to 3600 KWm. Both engines are EPA Tier 2 certified for stationary standby power applications.

ROLLS-ROYCE SOLUTIONS AMERICA (MTU)

Novi, Mich.

(248) 560-8000

www.mtu-solutions.com

POWER RANGE

Diesel: 100 to 13,410 hp

Gaseous Fuel: 40 to 3487 hp

Hydrogen: 250 kWe to 550 kWe; 760 to 2514 kWe

Corporate News

In June 2022, Rolls-Royce entered the hydrogen production market by acquiring a 54% majority stake in electrolysis stack specialist Hoeller Electrolyzer, whose technology is expected to form the basis of a new range of mtu electrolyzer products from its Power Systems business unit. Hoeller Electrolyzer, based in Wismar, Germany, is an early-stage technology company that is developing highly efficient polymer electrolyte membrane (PEM) stacks, under the brand name Prometheus, for the cost-effective production of hydrogen.

In March 2023, Rolls-Royce announced it had made significant investments in its manufacturing facilities in Aiken, S.C., and Mankato, Minn., to bring its mtu marine gen-set manufacturing capabilities to the U.S. in support of its contract to supply them for the U.S. Navy’s FFG program. This investment will also support future potential U.S. naval business. The company said the investments included new assembly tooling and material handling equipment, upgraded hoist systems, adapted test cells and building expansion, in addition to the creation of 20 new jobs.

Throughout 2022, the Power Systems division of Rolls-Royce released various mtu engines for use with EN15940 sustainable fuels. In addition to Gas to Liquid (GtL) and Coal to Liquid (CtL), these fuels include sustainable Biomass to Liquid (BtL), Hydrotreated Vegetable Oil (HVO), and Power to Liquid (PtL) fuels such as e-diesel.

The company said the advantages of HVO are clean combustion with a reduction in particulate emissions of up to 80%, nitrogen oxide emissions by an average of 8% and (depending on the manufacturing process and feedstock), CO2 emissions by up to 90% compared to fossil diesel. Testing confirmed that engines perform equally well when using HVO (compared to diesel) in terms of maximum power, load acceptance and fuel consumption. As a drop-in fuel, HVO requires no adaptations to the diesel plant infrastructure, hardware or software for its use.

In May 2022, diesel engines for MTU Series 1600 and 4000 gen-sets were approved for use with sustainable fuels. In addition, rail engines including the Series 1300, 1500 and 1800 were also released – these will be followed shortly by Series 1600 and 4000 engines for rail applications. Further, engines for construction machinery, industrial applications, agriculture and mining for the Series 1000, 1100, 1300, 1500 and 4000 followed in October of 2022. During 2023, marine diesel engines for Series 2000 and 4000 will also be approved for use with sustainable fuels.

In October of 2022, Rolls-Royce and Neste signed a Memorandum of Understanding to build a strategic partnership for the implementation of sustainable fuels for diesel engines. Both companies share a common vision: that sustainable fuels will play a key role in reducing greenhouse gas emissions in off-highway applications. The main components of the agreement are promoting the use of existing internal combustion engines for sustainable fuels, advancing the transition from fossil fuels to sustainable fuels, and HVO knowledge sharing.

Marine Engine News – Marine

Starting in 2023, the mtu Hybrid PropulsionPack became available for Series 2000 and 4000 applications. The Hybrid portfolio offers flexible propulsion solutions for yachts, ferries, tugboats and windfarm vessels. The system intelligently combines diesel engines with electric propulsion modules, batteries, gearboxes, control and monitoring systems and other electronic components to provide speed, comfort, efficiency and local emission-free cruising as required.

The Rolls-Royce 20V 4000 gen-set.

The Rolls-Royce 20V 4000 gen-set.

The Hybrid PropulsionPack is offered in a power range from 1119 kW to 4300 kW via diesel engines plus 165 kW to 743 kW via electric motors per powertrain, resulting in maximum propulsion power of 10,000 kW per vessel. To ensure the optimum propulsion solution for each type of ship, Rolls-Royce offers a modular kit with standardized components.

Rolls-Royce is also further developing its large marine engines for the Series 1163 and 8000 to comply with the IMO Tier III emissions directive. Starting in 2025, the engines will be available in all cylinder variants in the power range between 4800 and 10,000 KW. This will allow entry into Emission Controlled Areas (ECA), such as the Baltic and North Seas and off the North American coast. Rolls-Royce is also developing the necessary exhaust gas aftertreatment system with selective catalytic reduction (SCR) to adapt it precisely to mtu engines and customer requirements.

In March 2023, Rolls-Royce, Woodward L’Orange and WTZ Roßlau (Wissenschaftlich-Technisches Zentrum Roßlau) announced they have been working on a new joint project called MeOHmare. By the end of 2025, the three partners expect to develop a high-speed internal combustion engine concept for ships that can run on green methanol in a CO2-neutral manner. Rolls-Royce’s business unit Power Systems will develop an engine concept based on the Series 4000 that will be designed for low-emission, CO2-neutral and economical operation of ships with methanol.

Engine News – Power Generation

In July 2022, Rolls-Royce commissioned its first in-house test stand for hydrogen engines at its site in Augsburg, Germany. Over the past year and a half, the company has invested around 10 million euros at Augsburg in test bench modernization, hydrogen infrastructure and other measures as part of its “Net Zero at Power Systems” climate protection program. The company also successfully tested a 12-cylinder gas variant of the Series 4000 L64 engine running on 100% hydrogen fuel. The tests, carried out by the Power Systems business unit, showed very good characteristics in terms of efficiency, performance, emissions and combustion.

SCANIA U.S.A. INC.

San Antonio, Texas

(210) 403-0007

www.scaniausa.com

POWER RANGE

Diesel: 275 to 770 hp — Industrial

Diesel: 220 to 1150 hp — Marine (power levels above 800 hp are for pleasure craft only)

Engine News — Industrial Power Solutions

Scania offers U.S. EPA Tier 4 final and EU Stage 5 compliant, 9- 13- and 16-liter industrial engines. These engines are found in a variety of North American segments, including stationary, construction, material handling, agriculture, forestry and airport products. The ranges of output for Scania industrial engines are: 275 to 400 hp (9 L), 350 to 550 hp (13 L), and 550 to 770 hp for the 16 L engine.

Scania’s power generation engines for Tier 4 final consist of 9 L (208 to 240 kWe at 60 Hz), 13 L (264 to 328 kWe at 60 Hz) and 16 L (320 to 400 at 60 Hz), all rated for prime power applications.

Scania DC09 power gen engine.

Scania DC09 power gen engine.

The company said its engine management system and emission control system ensures a blend of customized performance and long-term operating economy.

Scania currently offers engine versions that meet US Tier 4 final, EU Stage 4 and 5, Stage 3A, and Stage 2 compliance for industrial applications.

Engine News — Marine Power Solutions

Due to its continuous effort to reduce gas emissions and support more sustainable marine operations, Scania has added seven new IMO Tier III compliant marine engines to its existing portfolio. The new DI13 have ratings of 257 kW, 280 kW, 284 kW, 331 kW, 368 kW, 405 kW and 441 kW at the rated speed of 2100 rpm widen the range of propulsion engines, in a commitment to further reduce NOx emissions. The new marine engines that are available in the heat exchanger or keel cooling systems, received type approval by the main classification societies and are ready for delivery to customers in 2023.

The broader selection of IMO Tier III engines offers customers more choices for different vessel requirements. The company said the marine propulsion engines are designed for prolonged operation in different applications, including passenger and road ferries, supply vessels, crew transfer vessels, pilot boats, as well as sea rescue and patrol boats.

Recently launched Scania pleasure craft engines encompass the 13 L and 16 L engine, and each build upon the company’s modular design approach.

The company said that by using its XPI fuel system, adding engine internals and blocks intended for commercial durability and longevity, it developed an engine rated up to 1150 hp.

The DI13 304M model allows customers and OEMs an extensive horsepower range from entry level 700 hp to a new 900 hp rating (925 hp for export). The V8 DI16 picks up the power range and carries it from 1000 hp up to 1150 hp. It uses single waste-gated turbo per bank.

Engine News—Alternative Fuel

Scania said its long-standing compatibility with alternative fuels such as HVO and biodiesel continue to meet customers’ needs for cleaner equipment. Scania has approved 100% HVO compatibility on all its engines, while biodiesel compatibility ranges from 10 to 100%.

Corporate News

Jörg Franzke was appointed president of Scania U.S.A. Inc., effective May 16, 2022 (see interview elsewhere in this issue), and Tomas Nilsson was named after sales director in July 2022. More recently, Andres Köhring joined Scania USA as sales manager for Industrial Products.

VOLVO PENTA OF THE AMERICAS

Chesapeake, Va.

(757) 436-2800

www.volvopenta.com/en-us/

POWER RANGE

Diesel: 143 to 796 hp (Industrial off-highway)

Diesel: 104 to 1020 hp (Industrial Power Generation)

Diesel: 12.2 to 1350 hp (Marine)

Gasoline: 200 to 430 hp (Marine-Aquamatic Stern Drive)

Corporate News