Cat’s C13D: The power of three

10 May 2023

At ConExpo, Caterpillar unveiled its next-generation engine platform, the C13D diesel. (Photo: Caterpillar)

At ConExpo, Caterpillar unveiled its next-generation engine platform, the C13D diesel. (Photo: Caterpillar)

There’s really no such thing as “one size fits all” when it comes to engines. But Caterpillar is coming about as close as it gets with its new C13D diesel, unveiled at ConExpo-Con/Agg 2023.

The new engine, the product of more than five years of development, is a 13 L platform that Cat said has a power density of up to 52.3 hp/L (40 kW/L) that enables it to cover an output range currently filled by its 13, 15 and 18 L engines. The new diesel is targeted toward a broad range of off-highway equipment, including rock crushers, screeners, grinders, trenchers, agricultural equipment such as tractors, harvesters and self-propelled sprayers, woodchippers, material handling equipment and large industrial pumps.

“It’s really about power density and it’s about the capability of this engine,” said Mark Stratton, Caterpillar vice president and general manager with responsibility for large industrial engines. “And it gives us the ability to take this platform and use it in applications where our competition – and our own platforms – were using much bigger engines in the past.

“Our C13B, which we sell today, our C15 and the bottom end of our C18 engine range will be covered by the power that this engine provides,” Stratton said.

The inline, six-cylinder C13D platform will offer eight power ratings from 456-690 hp (340-515 kW) with up to 2360 lb. ft. (3200 Nm) of peak torque. With bore and stroke dimensions of 129.5 x 162.5 mm, the turbocharged and aftercooled has an overall displacement of 12.9 L and incorporates a number of new design features, including:

- An engine block that incorporates optimized channels throughout the upper and lower water jackets in the cylinder head and block to ensure sufficient cooling and combustion thermal management, leading to improved durability

- A common rail fuel system incorporating the latest Caterpillar Zero-static Leak CR900 fuel injectors that Cat said are three times more robust than its existing MEUI-A (Mechanically actuated Electronically controlled Unit Injectors) system, used in conjunction with a 36,000 psi (250 MPa) capable fuel rail

- A new variable geometry turbocharger

- An oil-lubricated fuel transfer pump/high-pressure fuel pump combination that uses pressurized clean oil to lubricate its important components

- A fuel filtration module that consolidates the functionality of a dozen components into a single module, which incorporates new cartridge filter technology that eliminates the need for tertiary filters while allowing up to 1000-hour fuel filter change intervals, saving costs to total life of ownership

- An integral, filter-free passive crankcase ventilation and breather system that eliminates CCV servicing

By supplying comparable power and torque to Caterpillar’s current 13-, 15- and single-turbo 18 L engine platforms, Cat said the C13D platform provides an opportunity for original equipment manufacturers to downsize their engines and simplify design, assembly, and supply chain requirements across multiple applications. That consolidation can also reduce maintenance, parts and technical training, Caterpillar said.

“Today, we have three fantastic engines in what we call the heavy-duty inline six lineup – the C13B, the 15 L C15 and C18 single turbo, which is at the top of our engine range,” said David Nicoll, Product Line manager for large industrial engine development and the newly named president for Caterpillar’s Medium Wheel Products. “The C13D is going to be able to produce the power and efficiency across that entire line for our customers in the future.

“So as our customers begin to think about their future product development plans, they can use the C13D across that power range and essentially, engineer in the C13D where today they have the C13B, the C15 and the C18 single turbo,” Nicoll said. “That means that in cases where our customers have a wide range of products that take different engines, they can consolidate to one engine across that range. That helps them with their engineering, inventory, maintenance, aftermarket, all the things that come along with taking care of a machine that’s got an engine. That’s what the power of three means.”

What the power of three doesn’t mean, however, is that Cat engine customers will need to abandon the current 13, 15 and 18 L engines any time soon.

“We’re not going to force anyone to change over,” said Allen Chen, Product Marketing manager for Cat’s Industrial Power Systems Division. “We’re hoping that the value story tells itself – the C13D’s got more power, more torque, more altitude capability, and more cold start, less fuel consumption, less vibration, less noise – just everything that’s good about an engine.

Cat’s new C13D engine will offer ratings from 456 to 690 hp (340 to 515 kW) with up to 2360 lb. ft. (3200 Nm) of peak torque. (Photo: Caterpillar)

Cat’s new C13D engine will offer ratings from 456 to 690 hp (340 to 515 kW) with up to 2360 lb. ft. (3200 Nm) of peak torque. (Photo: Caterpillar)

“But we won’t force you to take it,” Chen said. “We understand and appreciate that it’s a very large engineering challenge to re-engineer an engine into a chassis. So we want to work with dealers and OEMs to determine when is the best time to change over.

“That being said, if and when EPA Tier 5, EU Stage 6 or let’s say China Nonroad 5 comes out, the current platforms – the C13B, the C15 and the C18 will not be certified to that next emissions level,” he said.

At launch, the C13D will meet the emissions standards of higher regulated markets, such as EU Stage 5, U.S. EPA Tier 4 final, China Nonroad 4, Korea Stage 5 and Japan 2014, equipped with Cat’s latest Clean Emissions Module (CEM). Engines for lesser regulated markets will also be offered, Cat said.

The CEM incorporates new high flow end caps and a new mixer designed to reduce fluids consumption. An in-cylinder dosing system and intake throttle valve regulates thermal management, removing the need for the Caterpillar Regeneration System (CRS), thereby reducing complexity.

The system also incorporates the company’s latest selective catalytic reduction (SCR) technology for improved efficiency across temperature ranges that Cat said delivers lower diesel exhaust fluid (DEF) consumption. The CEM package also includes a more compact packaging for the diesel oxidation catalyst (DOC) and diesel particulate filter (DPF).

The CEM can be mounted on the engine or remotely depending on application needs, the company said.

The Cat C13D engine platform enables the use of renewable liquid fuels such as 100% HVO, B100 distilled biodiesel and even up to B100 standard biodiesel, the company said. In addition, the engine’s core architecture is designed for the future development of natural gas and hydrogen fuel capabilities.

“We are 100% committed to the diesel platform as a platform for the future because we know our customers are going to need it,” Stratton said. “We’re fully embracing the energy transition and the need for alternative solutions.

“But if you need a diesel engine, if that’s the right answer, we want the best one on the market,” he said. “And even with an IC engine, there are alternatives that are coming to market today beyond our traditional diesel that lower our carbon footprint over the total lifecycle of the operation, things like HVO.

“It’s our expectation that this is our platform for the future for other alternative fuels, things like natural gas and hydrogen,” Stratton said. “And that’s why it’s so critical that we get the base engine right and we get the all the technology in place from the very beginning.”

Caterpillar said the C13D has amassed more than 12,000 hours in lab and initial field testing, with the first engine going to a customer for testing in the next few months. Pilot engines will be delivered to other test customers in 2025, with production scheduled to begin in 2026.

Cat all-in on engines

Much of the talk over the last few years has concerned technologies designed to replace internal combustion engines. But in unveiling its newest off-highway diesel, Caterpillar, the world’s largest manufacturer of engines and earthmoving equipment, made it clear it thinks there’s quite a bit of life left in engine technology.

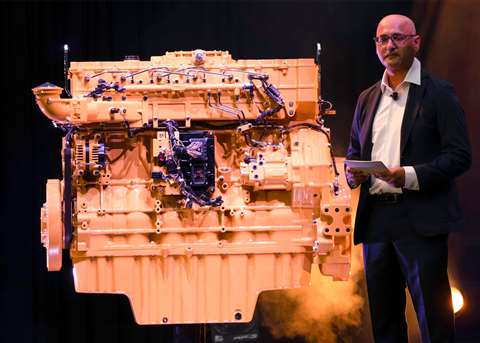

Jaz Gill, vice president of Sales, Marketing, Service and Aftermarket Parts for Caterpillar’s Industrial Power Systems Division, at the Las Vegas introduction of the C13D engine. (Photo: Caterpillar)

Jaz Gill, vice president of Sales, Marketing, Service and Aftermarket Parts for Caterpillar’s Industrial Power Systems Division, at the Las Vegas introduction of the C13D engine. (Photo: Caterpillar)

Calling the introduction of the new C13D diesel engine at ConExpo “a momentous day for Caterpillar,” Jaz Gill, vice president of Sales, Marketing, Service and Aftermarket Parts for Caterpillar’s Industrial Power Systems Division, noted that “every day now we’re waking up to new announcements, revolutionary new technologies providing different kinds of power.

“Whether it’s rechargeable batteries, hybrids or alternative fuels such as hydrogen or HVO and fuel cells, we know about all of these technologies, and indeed, we’re investing heavily in all of them,” he said. “And whilst all of these new technologies bode well for the future, I think it’s true to say, the tried and trusted internal combustion engine has been the primary workhorse for the vast majority of job sites around the world.

“So as Caterpillar, we’re dedicated to diesel,” Gill said. “We’re going to continue to invest. We see huge opportunities now, and in the future, for internal combustion engines.”

Cat’s battery energy storage technology

At the same time it was introducing a whole new engine concept, Caterpillar also used ConExpo-Con/Agg 2023 to highlight non-engine technologies that could also play a more significant role in the coming years.

Chief among these is the Cat Compact ESS, a mobile battery energy storage system (ESS) designed to supplement traditional mobile power solutions, which was displayed as part of the company’s Sustainability Hub at ConExpo. The new ESS modules, which were first unveiled at Bauma last fall, are targeted toward applications such as remote worksites that require long periods of low loads, such as nighttime loads, around the clock low loads, and time periods when a silent supply of energy is required.

Cat’s new Compact Energy Storage System (Photo: Caterpillar)

Cat’s new Compact Energy Storage System (Photo: Caterpillar)

Two ESS modules are available in 50 and 60 Hz configurations. The Cat XES60 ESS provides up to 56.8 kWh of energy storage capacity, while the XES120 delivers up to 127.9 kWh. Both enable full recharging in as little as four hours and incorporate advanced lithium-ion chemistry to provide thermal stability, high discharge/recharge efficiency and high cycle life, Caterpillar said.

The ESS modules have simple, straightforward connections that enable rapid plug and play installation and integration to any combination of diesel, natural gas or renewable energy source, including portable PV solar arrays or wind power, enabling quick and smooth worksite deployment. The modules store surplus power from the energy sources and discharge it on demand at the worksite.

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

CONNECT WITH THE TEAM